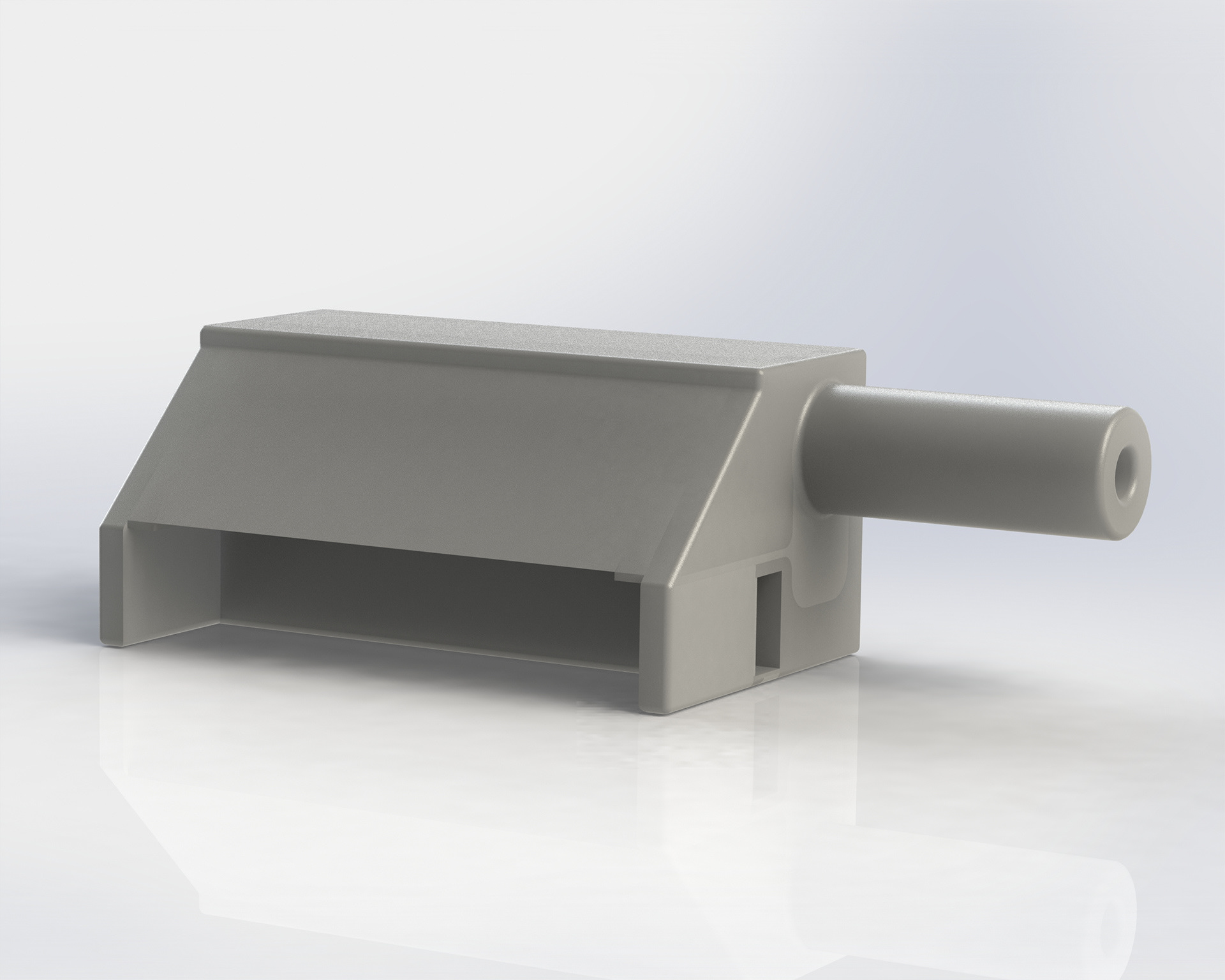

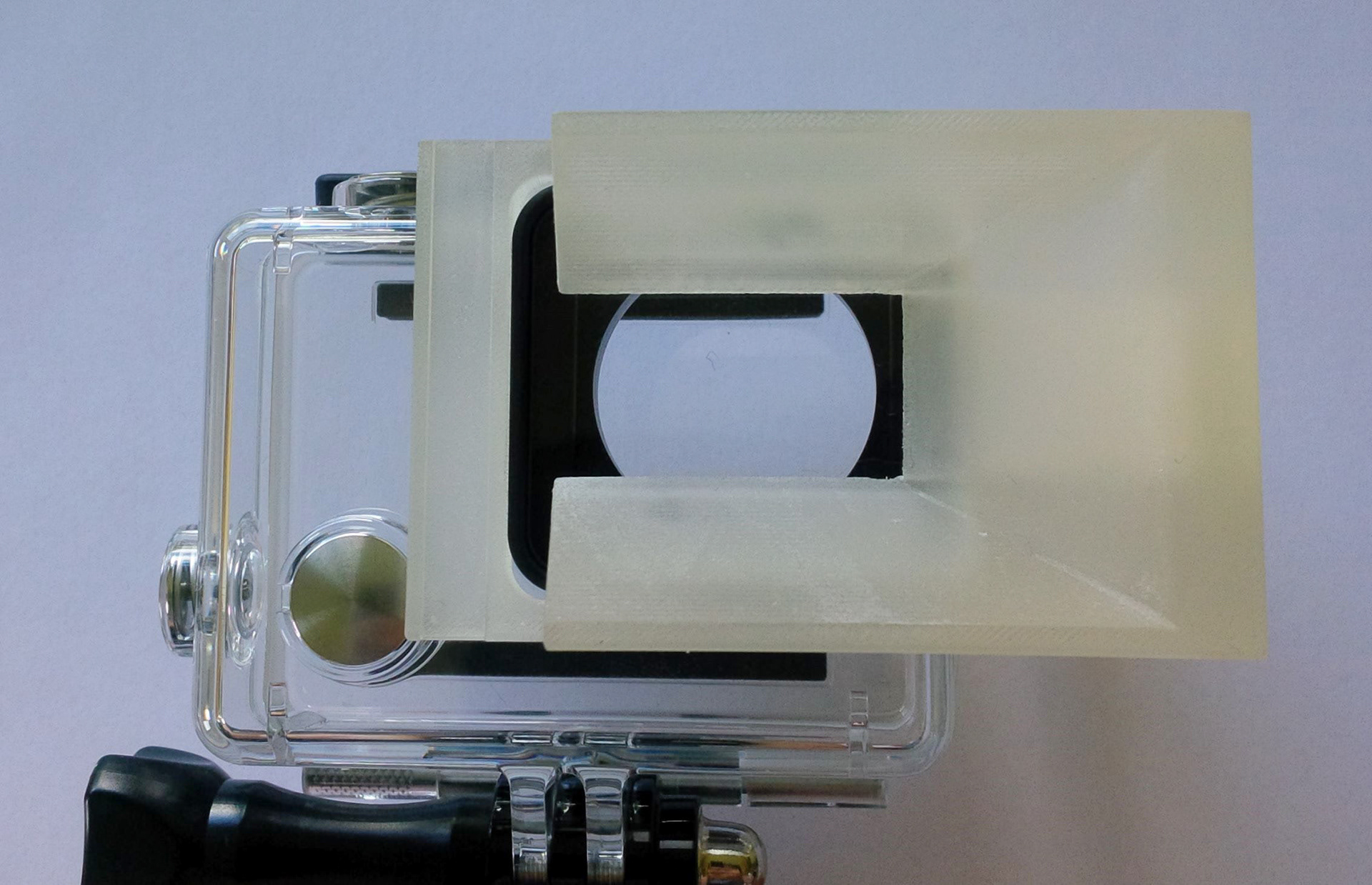

The final design consisted of thin channels that allowed air to pass over the lens of the camera, with an attachment point for an air compressor.

THE DESIGN PROCESS

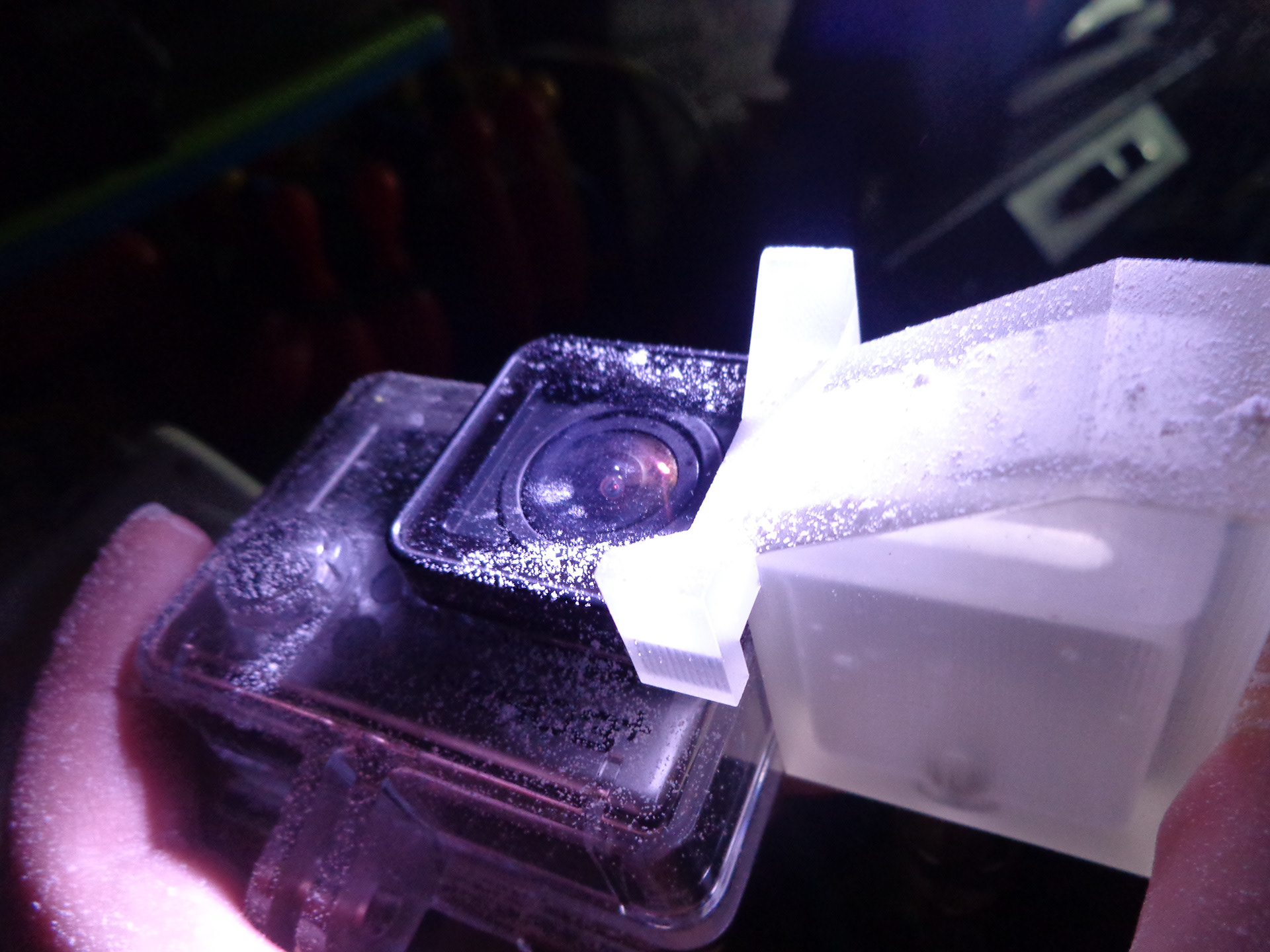

Cardboard prototyping was used initially to test the field of vision of the lens. Further low-tech testing included using flour to test how the 3D printed prototypes performed against dust, and how effective the air flow was.

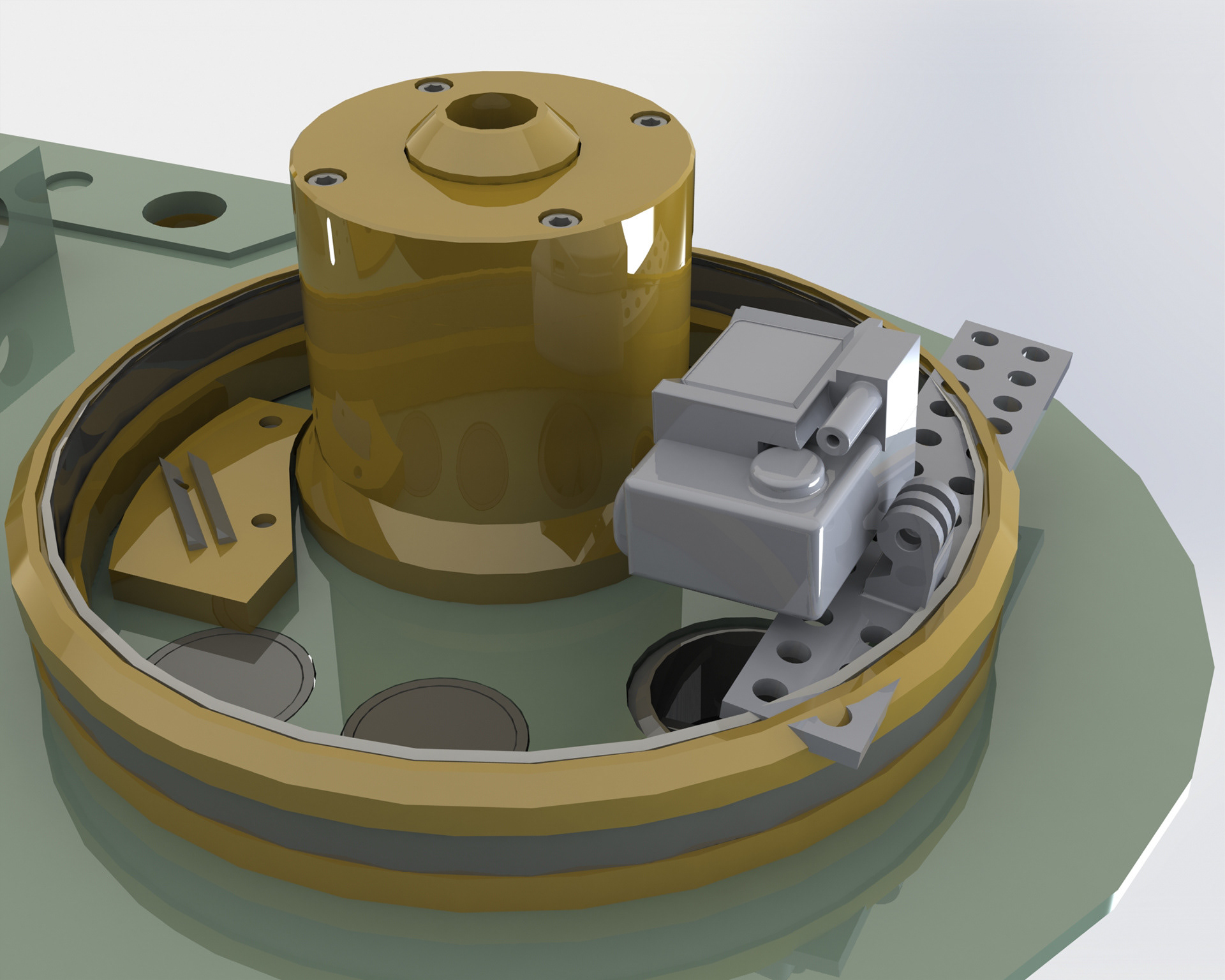

CAD was used to visualise and fit the product into the context of the industrial mixer. These CAD models were later used to 3D print prototypes that could be tested in the real environment.

Different forms designed and tested to find the best solution for the problem.

A later model being tested within a small mixer.

The final model in an industrial mixer and in use.